Phone : +91-9827113763 | +91-7587733050

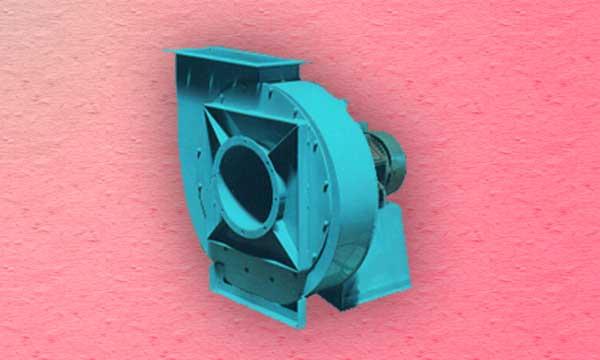

Cyclone Separator

Quick Overview

We are An ISO-9001:2015 certified company & air pollution control device cyclone separator manufacturers in Delhi India. Centrifugal collectors use cyclonic action to separate dust particles from the gas stream. In a typical cyclone, the dust gas stream enters at an angle and is spun rapidly. The centrifugal force created by the circular flow throws the dust particles toward the wall of the cyclone. After striking the wall, these particles fall into a hopper located underneath.

The most common types of centrifugal, or inertial, collectors in use today are:

- Single-cyclone : separators They create a dual vortex to separate coarse from fine dust. The main vortex spirals downward and carries most of the coarser dust particles. The inner vortex, created near the bottom of the cyclone, spirals upward and carries finer dust particles.

- Multiple-cyclone : separators Also known as multiclones®, consist of a number of small-diameter cyclones, operating in parallel and having a common gas inlet and outlet, as shown in the figure. Multiclones® operate on the same principle as cyclones—creating a main downward vortex and an ascending inner vortex.

Product Description

Multiclones® are more efficient than single cyclones because they are longer and smaller in diameter. The longer length provides longer residence time while the smaller diameter creates greater centrifugal force. These two factors result in better separation of dust particulates. The pressure drop of multiclone® collectors is higher than that of single-cyclone separators.

Cyclone systems consist of the following components:

- Ductwork and fan system

- A Inlet chamber

- Conical Shape

- Rotary Air Lock

- Outlet Duct

We Provided Complete System for following Industry

- Steel Induction Furnace

- Steel Re-rolling Mill Industry

- Sponge Iron Plant (DRI)

- Boiler (Heating process & Power Palnt)

- Lead Recycling Plant

- Aluminium Recycling Plant

- Copper Recycling Plant

- Dross Recycling Plant

- Slag Processing Unit

- Process Furnace

- Chemical Process Plant

- Casting Units

- Rice Mill Industry

- Wire (Binding) Industry

- Plywood Industry

- Paper Mill

- Lime Kiln

- Cement Kiln

- Textile Mill

- Fertilizer Plant

| To be Total Gas Volume in CFM | ********* CFM |

| Effective Height in meter | ********** m |

| Diameter in meter | ******* m |

| ID Fan | ******* Kw |

| Duct Size | ******** m |

| Water Pump Capacity | ******* Ltr/hr |